Services

Prototyping

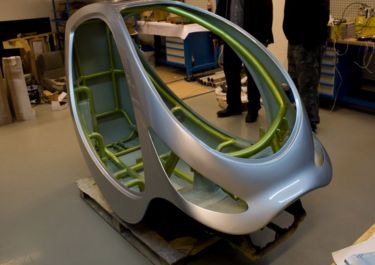

Ligthweight design services by CFRP/GFRP and biocomposite. Electric mobility is a challenge to vehicle makers and suppliers alike. It calls for innovative technologies that result in an increased range, for example through weight reduction. Sustainable lightweight design solutions with biocomposite materials are gaining in importance. Meshining Engineering provides services in field of CFRP/GFRP and bio composite lightweight design, simulation and prototype building.

NEED HELP?

Do you have further questions? Please don't hesitate to contact us. Our colleagues are happy to support you in realizing green ideas.

The only way for vehicles to meet CO2 emissions targets is to lose weight. To achive that it is required to introduce new materials like fiber-reinforced plastics. The exceptionally strength component feels very light in the hand.

MESHINING Engineering has been developing lightweight products made out of fiber-reinforced plastics (FRP) for a variety of structural components. Two types of composite materials are used: carbon fiber-reinforced plastics (CFRP) and glass fiber-reinforced plastics (GRP).

MESHINING Engineering Ltd. according to experience of design and production of convetional carbon- and glass-fiber-reinforced polymers developed new bio-composite, which consists of natural flax fibers as reinforcement and 100% bio matrix resin called Polylactid, PLA. These bio-composites are biodegradable and have very prosperous mechanical properties as well as competitive strength-to-weight ratio comparing to GFRP and CFRP. Furthermore due to the application of natural raw materials the bio-composites have environment friendly production process and recycling technology.

Request Quote

Would you download our actual brochures or should you have requests, questions about our products, services? Please fill in the form below, send us a short message. We are happy to support you and we will contact you soonest.